The recent Gartner Hype Cycle Report has highlighted the rising importance of AI in our daily lives, with modern technologies such as Computer Vision (CV) slowly approaching the plateau of productivity. Computer Vision has expanded into roles such as automated quality control, especially in manufacturing-related sectors. Moreover, as we approach the new era of industrial advancements, Industry 4.0, the advent of innovative technologies has transformed traditional quality assurance methods to automated quality assurance (AQA).

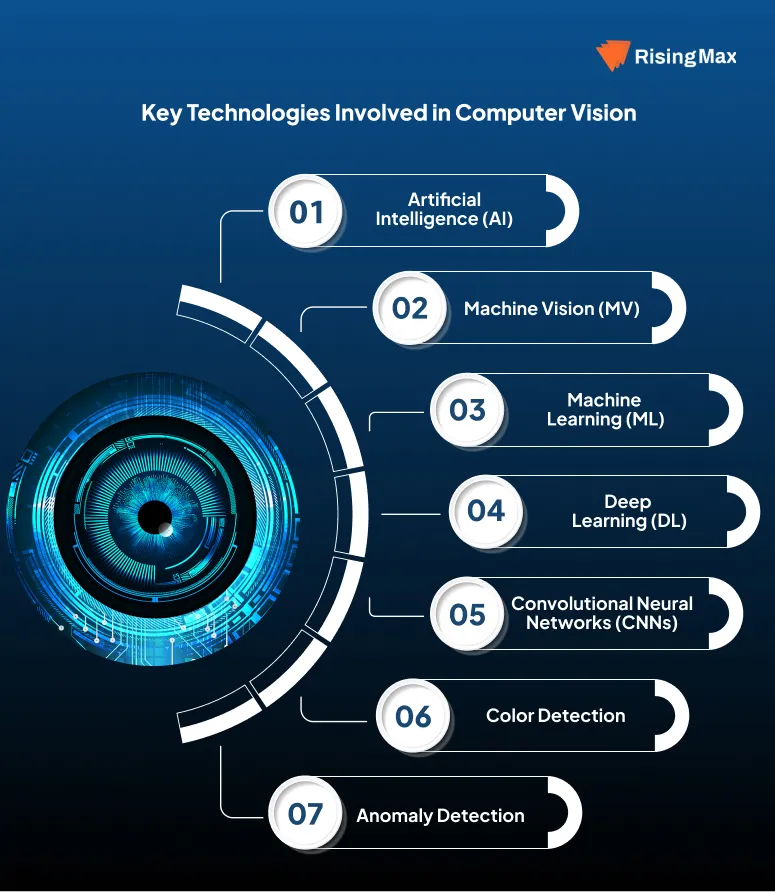

Automating quality control using computer vision and AI is a significant step (and is essential as well) towards building efficient Quality 4.0 frameworks that align with current technological advancements. In this article, we will discuss the mechanism and key technologies involved in Computer Vision (such as AI, Machine Vision, Machine Learning, Deep Learning, color detection, anomaly detection, etc.), industrial use cases of CV, application challenges, and future outlook towards integrated and real-time automated quality control frameworks using computer vision and AI.

Table of Contents –

- Pretext of Computer Vision, AI & Their Applications

- Working Mechanism of Computer Vision

- Key Technologies Involved in Computer Vision

- Practical Case Study of Working with Computer Vision

- Industrial Applications of CV and AI

- Market Giants Creating Successful Implementation

- Challenges and Limitations of Computer Vision and AI for Quality Control

- Establishing KPIs and ROI to Measure Real Results

- Conclusion

- Additional Readings

- FAQs

The Pretext of Computer Vision, AI & Their Applications

Traditional quality assurance methods, which rely heavily on manual human inspection, are increasingly viewed as limited due to their inherent subjectivity, time-consuming nature, and susceptibility to human error. The emergence of Automated Quality Assurance (AQA) addresses these challenges by integrating Artificial Intelligence (AI) and Computer Vision (CV) to automate inspection and control processes.

Computer Vision provides computers with the ability to perceive and understand the content of digital images and videos, while AI tools, such as Machine Learning (a subset of AI) and Deep Learning (further a subset of Machine Learning), enable these systems to autonomously reason and learn from data. Specifically, the use of Convolutional Neural Networks (CNNs) has revolutionized defect detection, enabling systems to identify minute inconsistencies with precision and speed often surpassing human capabilities.

This shift toward Quality 4.0 involves moving quality controls from manual, paper-based systems to the cloud, leveraging real-time data analysis and intelligent algorithms. By combining CV with Machine Vision (MV) components such as high-speed sensors and specialized lighting, manufacturers can achieve reliable inspection of high-end products.

For instance, Hyperspectral imaging vision can provide helpful information for critical tasks such as cancer detection, geological mapping, sorting plastic in recycling, detecting moisture in wood, or inspecting textiles. Similarly, computer imaging can be used to analyze a wide data set of images to record details that are impossible to see even with conventional MV techniques.

Understanding the Working Mechanism of Computer Vision

Computer Vision helps to interpret and analyze visual data using pattern recognition and learning-based techniques. CV can identify visual patterns, detect anomalies, and make decisions similar to human visual inspection, but more accurately. These high-quality image data and advances in computing power improve accuracy and reliability.

Earlier computer vision applications primarily depended on traditional machine learning algorithms, where engineers manually defined features such as edges, shapes, and textures. These approaches required large volumes of data, extensive rule-based programming, and continuous human supervision to maintain accuracy, especially when operating conditions changed.

Modern computer vision systems for quality control now rely largely on deep learning techniques. These systems use neural networks, particularly convolutional neural networks (CNNs), to automatically learn relevant visual features from labeled image data. By training on examples of acceptable products and defective samples, the system learns to recognize patterns, variations, and defects without the need for manual feature engineering.

Once trained, the model processes incoming visual data in real time to detect defects, classify products, and identify deviations from predefined quality standards.

Related Read | How Agentic AI in Clinical Workflow Can Solve $1 Trillion Coordination Burden

Key Technologies Involved in Computer Vision

The following table summarizes the core technologies and techniques that drive modern Computer Vision (CV) systems within industrial quality control.

| Technology | Core Function / Definition | Key Benefit in Quality Control |

| Artificial Intelligence (AI) | The overarching field is focused on creating autonomous reasoning and learning systems. | Enables the automation of industrial procedures and maintenance forecasting. |

| Machine Vision (MV) | The practical implementation of CV using specialized hardware such as sensors, lighting, and optics. | Provides high speed, accuracy, and repeatability for quantitative measurements on production lines. |

| Machine Learning (ML) | Algorithms that evolve and improve performance through a learning process without explicit programming. | Analyzes vast datasets to predict quality trends and identify potential issues. |

| Deep Learning (DL) | A subset of ML using multi-layered artificial neural networks to mimic human problem-solving. | Automatically extracts relevant features from raw data, handling high-volume, complex data. |

| Convolutional Neural Networks (CNNs) | A specific DL algorithm designed to identify spatial hierarchies like edges and textures. | Revolutionizes image classification and defect detection with high precision. |

| Color Detection | Digital measurement of color using color codification models such as Red, Green, and Blue (RGB). | Ensures reproducible color standards across sectors such as food processing and automotive painting. |

| Anomaly Detection | Algorithms (Clustering, Statistical, or ML-based) that identify deviations from normal patterns. | Flags outliers and irregularities (e.g., surface cracks or process shifts) in real-time. |

The effectiveness of Computer Vision (CV) in industrial quality control is driven by several interrelated technologies and techniques. Below is a detailed explanation of each key technology based on the sources:

Artificial Intelligence (AI)

AI is a broad subfield of computer science dedicated to developing intelligent agents or autonomous systems capable of reasoning, learning, and acting. In manufacturing, as discussed in this article, AI empowers businesses by automating industrial processes, enhancing quality assurance, and enabling predictive maintenance. It serves as the overarching framework that allows machines to perform tasks, such as medical diagnosis or quality inspection, that traditionally required human intelligence.

Machine Vision (MV)

While CV is the theoretical science of image understanding, Machine Vision is its practical realization in industrial environments. It refers to the specific methods, techniques, and hardware used to construct artificial vision systems for real-world applications. MV excels at quantitative measurements of structured scenes due to its high speed, accuracy, and repeatability. A typical Machine Vision System (MVS) consists of physical components like specialized lighting, optics, and image sensors (such as CCD or CMOS cameras) to capture visual data for processing.

In a whole, MVS (Machine Vision System) mainly consists of three components –

- Illumination

- Image capturing

- Image processing

Machine Learning (ML)

Machine Learning is a branch of AI that focuses on developing algorithms that allow a machine to evolve and improve its performance through a learning process without being explicitly programmed. In quality control, ML algorithms analyze vast amounts of data to predict potential quality issues and identify trends. These algorithms are generally categorized into:

- Black-box algorithms – Highly accurate but difficult to interpret (e.g., Deep Learning).

- Interpretable algorithms – Simpler models that allow humans to understand the reasoning behind a decision, crucial for high-stakes fields like finance or security.

Deep Learning (DL)

A specialized subset of Machine Learning, Deep Learning utilizes artificial neural networks with multiple layers to mimic the human brain’s approach to problem-solving. Each layer builds upon the output of the previous one, allowing the system to automatically extract relevant features from raw data. This eliminates the need for manual feature engineering and allows the system to handle large, complex datasets typical of high-volume manufacturing environments.

When it comes to automating quality control using computer vision and AI, a further subset of DL is used, namely, Convolutional Neural Networks (CNNs).

Convolutional Neural Networks (CNNs)

CNNs are the cornerstone of modern computer vision and a specific type of Deep Learning algorithm. They are designed to automatically learn spatial hierarchies of features, such as edges, textures, and shapes, by breaking images down into pixels and applying mathematical operations called convolutions. CNNs are particularly effective for image classification and defect detection, as they can be retrained to adapt to new product designs or specific defect types.

Color Detection and Measurement

In many industries, such as food processing, color is a primary attribute used to judge quality. CV systems measure color more rigorously than the human eye by using codification models like Red Green Blue (RGB), which represent colors as digital numbers that software can interpret. This allows for reproducible representations of color and the ability to trigger alerts if a product deviates from a specific color space or standard.

Anomaly Detection

Anomaly detection algorithms are essential for identifying deviations from normal operational patterns, which often signal defects or process failures. Common techniques include:

- Clustering – Grouping similar data points to identify outliers that do not fit the norm.

- Statistical Methods – Establishing thresholds based on historical data; any data point surpassing these limits is flagged.

- ML-Based Detection – Advanced models like Isolation Forest that learn normal patterns and identify irregularities without needing previously labeled data.

Related Read | How RAG and MCP Can Help Reduce AI Hallucinations – A Technical Guide

Understanding the Working Mechanics of Computer Vision Using a Practical Case Study

Case Study in focus – Real-time monitoring of robotic building construction.

To understand the working principle of computer vision and how it applies in real-life scenarios, we have included two important case studies of the application of computer vision (CV) in the real-time monitoring of robotic building construction.

This case study examines a laboratory-scale extrusion system designed to monitor and control the quality of printed layers in real-time.

Technical Implementation and Setup

The system’s hardware configuration is designed for high-speed, on-site data acquisition. It utilizes a Logitech 720p camera firmly attached to the extruder via a custom 3D-printed mount. To maintain consistent visual data, the camera is positioned exactly 40cm above the top surface of the extruded layer. Data processing is handled at the edge by a Raspberry Pi 3 Model B, which analyzes the extrusion videos as they are captured.

Algorithmic Workflow

The CV algorithm focuses on a shape-based approach rather than color or texture, as these can be unreliable for detecting slender, monochromatic objects like concrete. The workflow follows a precise sequence:

- Preprocessing

- Segmentation

- Measurement

- Defect Detection

Results and System Performance

Experimental findings confirm that the vision-based system is both highly precise and responsive. A significant breakthrough of this study is the proof of feasibility for a closed-loop extrusion system; the extruder can automatically adjust its parameters to meet target dimensions without requiring prior calibration for different printable mixtures.

Critical Analysis and Limitations

While successful, the study identifies several technical bottlenecks that must be addressed for industrial-scale adoption:

- Computational Constraints – The use of a single-card computer (Raspberry Pi) can limit performance in more complex or high-speed environments compared to more robust embedded computers.

- Repairability – The miniaturized nature of the system’s components increases overall reliability by reducing the number of connectors, but it makes repairs difficult or impossible once a component failure occurs.

- Accuracy Thresholds – Higher precision in these systems is often governed by tight convergence criteria, which can lead to longer computation times and slower performance if image sizes are too large.

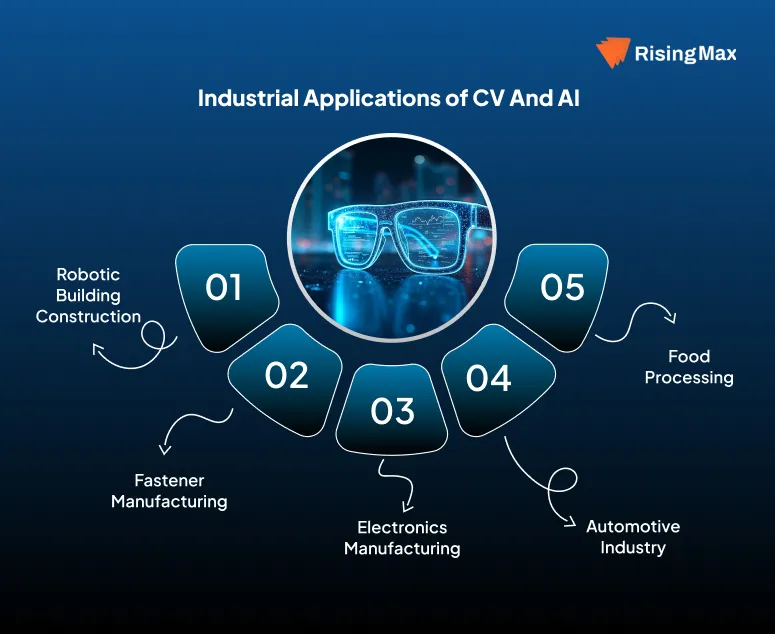

Industrial Applications of CV and AI: Results and Critical Analysis

The integration of Computer Vision (CV) and Artificial Intelligence (AI) has moved beyond theoretical research into diverse industrial sectors, proving to be a cornerstone of Industry 4.0. Below are several practical cases illustrating the real-world results and critical limitations of these technologies.

1. Robotic Building Construction (Extrusion Monitoring)

In the construction sector, CV is used for real-time quality monitoring during robotic concrete printing. A system using a standard 720p camera and a Raspberry Pi measures the width of extruded layers to detect over- or under-extrusion, such as tearing or discontinuities.

Result: The system demonstrated high precision and responsiveness under experimental conditions, proving that a vision-based extruder can automatically adjust parameters without prior calibration.

Critical Analysis: A significant limitation is the computational constraint of using single-card computers, which can limit performance in complex environments. Furthermore, the system’s reliability is high, but its miniaturized components make repairs difficult or impossible once a failure occurs.

2. Fastener Manufacturing (Bolts and Screws Inspection)

Automated systems are employed to inspect bolts and screws on production lines using Convolutional Neural Networks (CNNs) and edge processing hardware like the Intel Neural Compute Stick.

Result: The technology effectively identifies color defects, orientation issues, and surface cracks that are often invisible to the naked eye, automatically removing non-conforming parts from the assembly line.

Critical Analysis: The study revealed that the active contour method used for segmentation frequently gets stuck in local minimum states, leading to computational complexity. Additionally, this method often overlooks minute features and performs slowly when processing large image sizes, making it less ideal for high-speed video operations.

3. Electronics Manufacturing (PCB Inspection)

Automated Optical Inspection (AOI) is vital for inspecting Printed Circuit Boards (PCBs). These systems use high-resolution cameras and ML algorithms to verify component placement and identify soldering defects.

Result: AOI systems operate at extreme speeds, significantly reducing inspection time compared to manual labor and providing real-time feedback to the production line to minimize waste.

Critical Analysis: A primary challenge here is the need for large labeled datasets; without sufficient data diversity, models risk overfitting, where they only recognize specific defects they have seen before and fail to generalize to new board designs.

4. Automotive Industry (Paint and Surface Quality)

Automotive manufacturers utilize CV for paint defect detection and general assembly quality checks. Systems analyze color consistency and identify surface scratches or uneven coverage using 3D imaging and specialized lighting.

Result: This ensures consistent branding standards and prevents defective vehicles from reaching the market, thereby protecting brand reputation.

Critical Analysis: The main hurdle is legacy system integration. Many automotive plants use older equipment that lacks interoperability with modern AI protocols, leading to data silos that make it difficult to access the comprehensive datasets required for predictive analytics.

5. Food Processing (Contaminant Detection and Color Grading)

In the food industry, color is the primary attribute used by consumers to judge freshness. CV systems measure color using the RGB (Red, Green, Blue) model and inspect products for foreign objects like metal, plastic, or glass.

Result: CV provides a more rigorous and reproducible measurement of quality than trained human inspectors, whose judgments are often subjective. It effectively prevents contaminated products from reaching consumers.

Critical Analysis: While highly accurate, the complexity of training models for diverse and irregularly shaped food products is significant. Furthermore, human oversight is still occasionally required for qualitative interpretation of complex, unstructured scenes where MV systems, which excel at structured quantitative measurement, might struggle.

Advanced Industrial Use Cases & Integration Strategies

How can Digital Twins improve predictive quality management in factories?

Digital twins serve as virtual replicas of physical systems, acting as a critical innovation for predictive quality management within the framework of Industry 4.0. These systems function by integrating real-time data from production processes to provide a detailed view of equipment performance and product quality. By analyzing this live data alongside historical patterns, digital twins use predictive analytics to forecast potential quality issues before they actually occur.

This technology improves factory operations through several key mechanisms:

- Proactive Corrective Actions – Because potential defects are predicted in advance, organizations can implement adjustments to the production line early, preventing the creation of defective items.

- Scenario Testing and Simulation – Digital twins allow manufacturers to test different production scenarios in a virtual environment. This enables them to evaluate how specific changes might impact quality, supporting data-driven decision-making and process optimization without risking physical resources.

- Continuous Feedback Loops – The insights gained from simulations inform improvements across the entire spectrum of production, from initial design to quality assurance strategies.

- Holistic Lifecycle Management – They provide a total view of the product lifecycle, ensuring quality standards are monitored and maintained from the design phase through to end-use.

Ultimately, the integration of digital twins allows for autonomous quality control within smart manufacturing ecosystems, reducing the need for manual intervention and significantly enhancing operational resilience.

What role does edge computing play in real-time inspection?

Digital twins serve as virtual replicas of physical systems, acting as a critical innovation for predictive quality management within the framework of Industry 4.0. These systems function by integrating real-time data from production processes to provide a detailed view of equipment performance and product quality. By analyzing this live data alongside historical patterns, digital twins use predictive analytics to forecast potential quality issues before they actually occur.

This technology improves factory operations through several key mechanisms:

- Proactive Corrective Actions – Because potential defects are predicted in advance, organizations can implement adjustments to the production line early, preventing the creation of defective items.

- Scenario Testing and Simulation – Digital twins allow manufacturers to test different production scenarios in a virtual environment. This enables them to evaluate how specific changes might impact quality, supporting data-driven decision-making and process optimization without risking physical resources.

- Continuous Feedback Loops – The insights gained from simulations inform improvements across the entire spectrum of production, from initial design to quality assurance strategies.

- Holistic Lifecycle Management – They provide a total view of the product lifecycle, ensuring quality standards are monitored and maintained from the design phase through to end-use.

Ultimately, the integration of digital twins allows for autonomous quality control within smart manufacturing ecosystems, reducing the need for manual intervention and significantly enhancing operational resilience.

How do AQA systems integrate with existing manufacturing workflows?

Automated Quality Assurance (AQA) systems are designed to be seamlessly integrated into existing manufacturing workflows, a process that minimizes operational disruptions while significantly enhancing throughput. This integration occurs through several physical, technical, and data-driven layers:

- Physical and Hardware Integration.

- Real-Time Feedback Loops

- Edge and Cloud Connectivity

- Industry 4.0 Ecosystems

Challenges to Integration

Despite the benefits, integrating AQA into existing workflows presents several significant hurdles:

- Many factories operate with older legacy systems that utilize varying protocols and standards, making it difficult to establish a seamless data flow with modern AI platforms.

- Data is often stored in isolated environments across different departments, which complicates the gathering of the comprehensive, labeled datasets required to train effective machine learning models.

- Upgrading existing infrastructure to support AQA can be resource-intensive, costly, and complex, often requiring a significant initial investment in new sensors and computational hardware.

To ensure success, the sources recommend cross-functional collaboration between IT, operations, and quality assurance teams to align technology solutions with specific operational needs.

Market Giants Creating Successful Implementation of Predictive Maintenance & Computer Vision

Several market giants have begun to integrate AI and modern technologies in their workflow, including the manufacturing and production businesses. In this section, we have discussed some practical use cases that market leaders have achieved successfully. The following use cases mostly include predictive maintenance demonstrations using advanced techniques such as computer vision, machine vision, machine learning, and AI.

The following case studies are taken from the research paper “Automated Quality Assurance Using AI and Computer Vision” published by Owen, Antony & Hannah, James. (2021).

1. General Electric (GE)

General Electric has succeeded in implementing predictive maintenance using computer vision in its aviation division. GE takes advantage of advanced analytics and machine learning to collect data from aircraft engines and analyzes it to set maintenance routines. As a result, the company reported a reduction in unplanned downtime and maintenance costs, leading to better operational efficiency.

2. Siemens

Similar to GE, Siemens also has integrated predictive maintenance in its workflow. They have deployed AI/ML-assisted predictive maintenance into their manufacturing process of gas turbines. With the help of algorithms, the company is able to gather sensor data from turbines and predict failures or scheduled maintenance proactively.

3. Rolls-Royce

Rolls-Royce has developed and deployed an “Engine Health Monitoring” system across its aviation division. The computer vision-enabled system continuously monitors engine performance data and uses machine learning algorithms to predict potential issues in advance. Resultantly, the company is able to achieve savings in operational costs and improved engine performance reliability for its customers.

4. Bosch

Bosch has successfully applied predictive maintenance techniques in its manufacturing plants. By analyzing data from production machinery, Bosch can detect anomalies and predict equipment failures. This proactive approach has resulted in reduced downtime, optimized maintenance schedules, and enhanced overall productivity.

5. Schneider Electric

Schneider Electric implemented computer vision & predictive maintenance in its facilities to monitor critical equipment in real time. By leveraging IoT sensors and advanced analytics, the company can anticipate failures and optimize maintenance activities. This initiative has led to improved equipment uptime and significant cost savings, showcasing the benefits of predictive maintenance in industrial settings.

Predictive maintenance models are built upon key components such as data collection, analysis, and decision-making processes.

Challenges and Limitations of Computer Vision and AI for Quality Control

While Automated Quality Assurance (AQA) systems offer transformative benefits, their successful implementation is frequently hindered by significant technical, data-related, and organizational challenges.

1. Data-Related Requirements and Constraints

The effectiveness of AI-driven quality control is heavily dependent on the quality and availability of data.

Need for Large Labeled Datasets – Machine learning models, particularly deep learning architectures, require vast amounts of labeled data to train effectively. In many industrial settings, defects are rare or vary widely, making it difficult and resource-intensive to gather a sufficiently diverse dataset.

Risk of Overfitting – When training data is insufficient or lacks diversity, models may suffer from overfitting, where they learn to recognize only specific examples they have already seen rather than generalizing to new, unseen defects.

Data Silos and Integration – In many organizations, critical quality data is stored in isolated silos across different departments, complicating the creation of the comprehensive datasets required for holistic analytics.

2. Technical and Algorithmic Complexities

The mathematical models and hardware used in Computer Vision (CV) have inherent limitations that can impact real-time performance.

Algorithmic Bottlenecks – Specific techniques like the active contour method, often used for segmentation, can get stuck in local minimum states, requiring complex simulated annealing techniques to overcome. Furthermore, these algorithms may overlook minute features and struggle to segment objects that are positioned very close together.

Accuracy vs. Computation Time – High-precision inspection often requires tighter convergence criteria, which leads to longer computation times. This presents a significant challenge for high-speed production lines where decisions must be made in milliseconds.

Computational Hardware Constraints – While edge devices like the Raspberry Pi facilitate local processing, they have computational caps that can limit performance in complex environments. Additionally, the miniaturization of these components often makes repairs difficult or impossible following a hardware failure.

3. Integration and Infrastructure Challenges

AQA systems do not operate in a vacuum and must be integrated into existing manufacturing ecosystems.

Legacy System Compatibility – Many factories utilize legacy equipment that lacks the communication protocols or standards necessary to interface with modern AI and IoT platforms.

Data Flow Disruptions – Any deterioration or disruption in the data flow can hinder the effectiveness of quality assurance efforts and compromise the audit trail required for regulatory compliance.

Integration Costs – Transitioning to AQA involves a high “change overhead,” including significant initial investments in sensors, high-speed processing infrastructure, and the potential for temporary operational disruptions during rollout.

4. Human Factors and Qualitative Limitations

Despite the power of AI, human oversight remains irreplaceable in specific contexts.

Qualitative vs. Quantitative Analysis – While Machine Vision (MV) excels at the quantitative measurement of structured scenes (e.g., measuring a bolt’s width), human inspectors are still superior for the qualitative interpretation of complex and unstructured scenes.

Workforce Adaptation and Skill Gaps – The transition to AQA requires a workforce skilled in data analysis and machine learning. Many organizations face a significant skill gap, alongside cultural resistance from employees who may fear job displacement due to automation.

Establishing KPIs and ROI to Measure Real Results

As discussed in the previous section regarding the main hurdles that an organization has to face while integrating computer vision and AI, it becomes imperative to measure the implementation of new technology in industrial workflow with the help of established KPIs and ROI.

To justify the investment and ensure long-term viability, organizations must track the following metrics:

- Downtime Reduction (Measuring Uptime): The percentage decrease in unplanned downtime resulting from proactive AQA and predictive maintenance.

- Maintenance Cost Savings: The financial delta between expensive emergency repairs and scheduled, proactive interventions.

- Predictive Model Accuracy: A rigorous comparison of predicted quality outcomes versus actual production results.

- Mean Time Between Failures (MTBF): A key metric for assessing improvements in overall equipment reliability.

- Employee Engagement and Satisfaction: A leading indicator of successful technology adoption; high workforce sentiment correlates with lower implementation friction and higher long-term ROI.

- Total ROI: A comprehensive analysis of initial capital expenditure versus long-term gains in labor savings, waste reduction, and increased throughput.

Continuous Improvement: Model Refinement and Future-Proofing

Automating quality control using computer vision is a lifecycle, not a one-time project. Therefore, for better results, these CV models need continuous refinement, such as

- Real-Time Data Monitoring: Maintenance teams must utilize dashboards and alert systems for immediate visibility into equipment anomalies.

- Regular Model Retraining: Models must be updated periodically to adapt to changing operational contexts, new product designs, or shifting environmental conditions.

- Digital Twins: Future-proof the facility by developing virtual replicas of physical systems. These digital twins allow for the simulation of quality outcomes and the prediction of potential issues before they manifest on the physical line.

Conclusion

Automating quality control through Computer Vision (CV) and Artificial Intelligence (AI) represents a structural transformation within Industry 4.0 ecosystems. By integrating Machine Vision hardware, edge and cloud computing architectures, and advanced learning models such as Convolutional Neural Networks (CNNs), Automated Quality Assurance (AQA) systems shift quality management from subjective, manual evaluation to objective, real-time, and continuously adaptive control mechanisms.

Sustainable success in Quality 4.0 requires more than technological adoption. Industrial case studies across construction, fastener manufacturing, PCB inspection, automotive finishing, and food processing demonstrate measurable gains in precision, reduced downtime, and greater cost efficiency.

Additional Readings –

This article is based on the findings and discussions conducted in following research publications; for further reading, refer to the following papers.

- A, John Rajan & Kandasamy, Jayakrishna & Vignesh, T. & Chandradass, J. & Mahadevan, Ttm.Kannan. (2021). Development of computer vision for inspection of bolt using convolutional neural network. Materials Today: Proceedings. 45. 10.1016/j.matpr.2021.01.372.

- Ali Kazemian, Xiao Yuan, Omid Davtalab, Behrokh Khoshnevis. Computer vision for real-time extrusion quality monitoring and control in robotic construction. Volume 101, 2019, Pages 92-98, ISSN 0926-5805. https://doi.org/10.1016/j.autcon.2019.01.022

- Owen, Antony & Hannah, James. (2021). Automated Quality Assurance Using AI and Computer Vision.

- Abdelfatah Ettalibi, Abdelmajid Elouadi, Abdeljebar Mansour, AI and Computer Vision-based Real-time Quality Control: A Review of Industrial Applications, Procedia Computer Science, Volume 231, 2024, Pages 212-220, ISSN 1877-0509, https://doi.org/10.1016/j.procs.2023.12.195.

FAQs

Q1. What is Automated Quality Assurance (AQA) in manufacturing?

Ans. Automated Quality Assurance (AQA) is the use of Computer Vision (CV), Artificial Intelligence (AI), and Machine Learning (ML) to automatically inspect, detect, and control product quality in real time. Unlike manual inspection, AQA systems use cameras, sensors, and deep learning models (such as CNNs) to identify defects, measure dimensions, detect anomalies, and trigger corrective actions without human intervention.

Q2. How does Computer Vision improve industrial quality control?

Ans. Computer Vision improves industrial quality control by analyzing high-resolution image data to detect defects, classify products, measure dimensions, and identify deviations from quality standards. Using deep learning models, especially Convolutional Neural Networks (CNNs), CV systems automatically learn visual patterns and perform real-time inspection with higher speed, consistency, and repeatability than human inspectors.

Q3. What is the difference between Computer Vision and Machine Vision?

Ans. Computer Vision (CV) is the theoretical field focused on enabling machines to interpret and understand visual data. Machine Vision (MV) is the practical industrial implementation of CV using hardware components such as cameras, lighting systems, sensors, and optics. CV provides the algorithms and intelligence, while MV provides the physical infrastructure for image acquisition and processing.

Q4. Why are Convolutional Neural Networks (CNNs) important in defect detection?

Ans. Convolutional Neural Networks (CNNs) are essential in defect detection because they automatically learn spatial hierarchies such as edges, textures, and shapes directly from pixel data. Unlike traditional rule-based systems, CNNs eliminate manual feature engineering and achieve high-precision image classification and segmentation, making them ideal for surface crack detection, PCB inspection, paint analysis, and fastener validation.

Q5. How does anomaly detection work in AI-based quality control?

Ans. Anomaly detection identifies deviations from normal production patterns using clustering methods, statistical thresholds, or machine learning models. These systems learn what “normal” data looks like and flag outliers such as surface cracks, misalignments, process shifts, or irregular color distributions. Advanced ML-based approaches can detect anomalies even without labeled defect data.

Q6. What role does edge computing play in real-time inspection?

Ans. Edge computing enables real-time inspection by processing visual data locally on embedded devices (e.g., Raspberry Pi or industrial edge processors) instead of sending it to the cloud. This reduces latency, supports millisecond-level decision-making, maintains operational continuity during connectivity issues, and enables closed-loop control systems that instantly adjust production parameters.

Q7. How do digital twins enhance predictive quality management?

Ans. Digital twins are virtual replicas of physical manufacturing systems that integrate real-time sensor and vision data. By combining live operational data with historical trends, digital twins simulate scenarios, forecast potential defects, and optimize production parameters. This enables proactive corrective actions, lifecycle quality management, and autonomous decision-making within Industry 4.0 frameworks.

Q8. What industries benefit most from AI-driven quality control?

Ans. Industries that benefit significantly include:

- Construction (robotic extrusion monitoring)

- Fastener manufacturing (bolt and screw inspection)

- Electronics (PCB Automated Optical Inspection – AOI)

- Automotive (paint and surface defect detection)

- Food processing (color grading and contaminant detection)

These sectors require high-speed, high-precision, repeatable inspection processes.

Q9. What are the main challenges of implementing AI in quality control?

Ans. Key challenges include:

- Requirement for large, diverse labeled datasets

- Risk of model overfitting

- Integration with legacy manufacturing systems

- Computational constraints at the edge

- High initial infrastructure costs

- Workforce skill gaps in AI and data analytics

Successful implementation requires cross-functional collaboration and strategic modernization.

Q10. How is predictive maintenance related to Computer Vision?

Ans. Predictive maintenance uses AI and machine learning to analyze visual and sensor data to forecast equipment failures before they occur. Computer Vision systems monitor equipment conditions, detect early-stage anomalies, and integrate with predictive analytics models to reduce unplanned downtime, extend asset life, and optimize maintenance schedules.

Q11. How do AI-based quality systems reduce downtime?

Ans. AI-based quality systems reduce downtime by:

- Detecting defects in real time

- Enabling proactive maintenance through predictive analytics

- Automatically adjusting production parameters via closed-loop control

- Identifying early-stage anomalies before failure

This leads to improved Mean Time Between Failures (MTBF) and reduced emergency repair costs.

Q12. What KPIs should be tracked to measure the ROI of Automated Quality Assurance?

Ans. Organizations should track:

- Downtime reduction percentage

- Maintenance cost savings

- Predictive model accuracy

- Mean Time Between Failures (MTBF)

- Defect rate reduction

- Throughput improvement

- Total ROI (capital expenditure vs. long-term gains)

These KPIs validate both technical performance and financial impact.

Q13. Why is continuous model retraining necessary in AI-driven quality systems?

Ans. Continuous model retraining is necessary because production environments evolve. Changes in product design, raw materials, lighting conditions, or operating parameters can reduce model accuracy over time. Regular retraining ensures adaptability, prevents performance drift, and maintains high defect detection precision.

Q14. Can AI completely replace human quality inspectors?

Ans. AI significantly enhances inspection accuracy and speed, particularly in structured, quantitative tasks. However, human oversight remains essential for qualitative interpretation, complex unstructured scenarios, ethical governance, and strategic decision-making. The most effective approach is human and AI collaboration rather than full replacement.